How to implement asset circularity with equipment traceability?

Sustainability is a multi-dimensional challenge

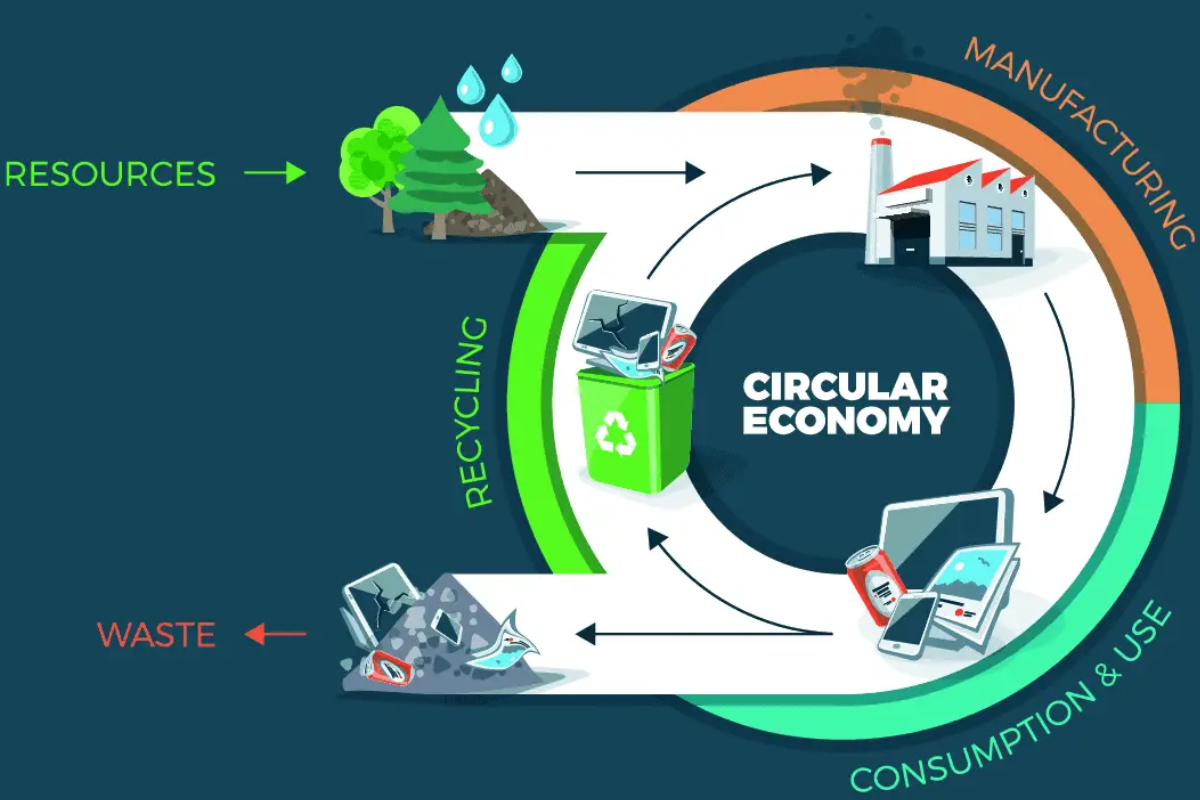

With shrinking access to raw materials and natural resources and growing constraints on Energy availability, product end-of-life can no longer mean waste.

Circular Economy enables Real & Substantial CO2 emissions reductions

Emissions of the EEE sector could decrease by 43% by focusing on the recycled content of materials in EEE and could be divided by two if efforts were made on the increase of the reuse of EEE

Circularity starts with systematic, and reliable Asset traceability and ownership registration

Global industrial markets are complex. When selling through global channels manufacturers often lose track of the final owner of their products and are not often in a position to properly handle the assets’ end of life

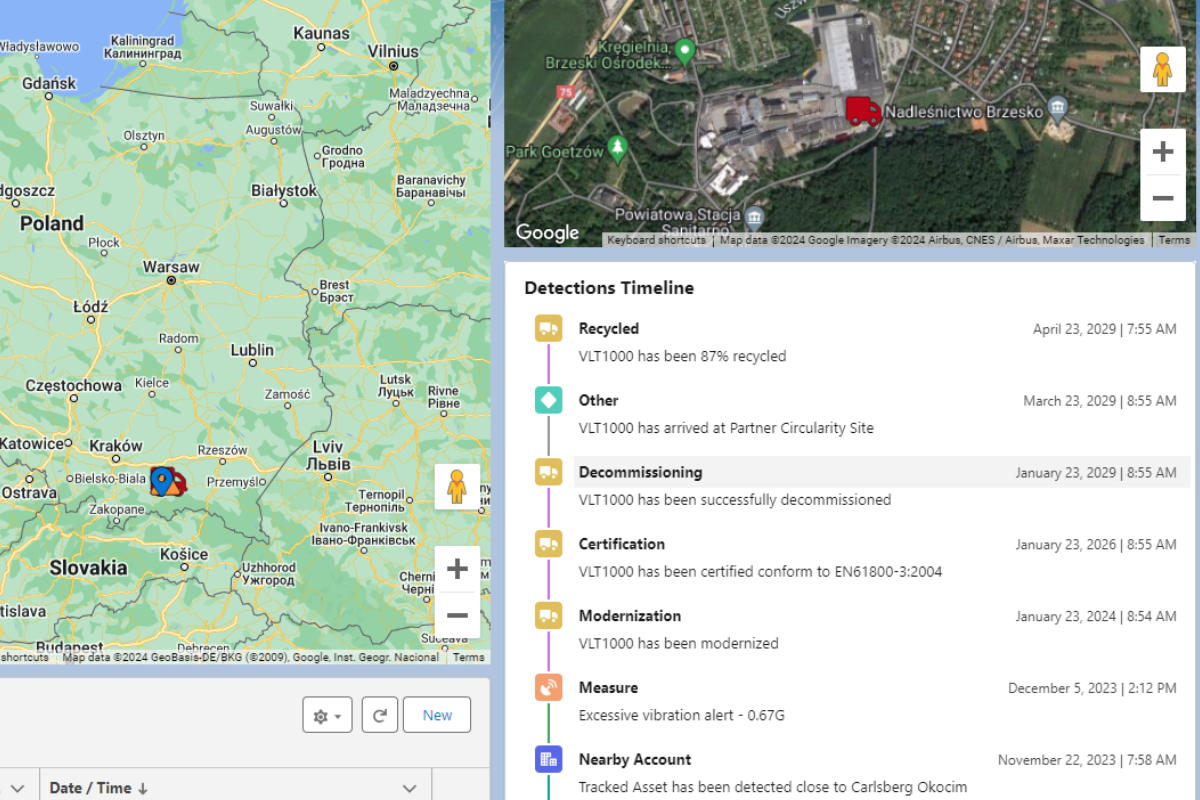

Wisechain's Platform registers equipment ownership and plans reverse logistics activities

Wisechain enables manufacturers with multiple ways to register a product to a site and owner to plan future take-back activities, with dedicated partners, directly in Salesforce.

Special Features

- Multiple asset location capture methods

- AI-Powered ownership registration

- Asset lifetime timeline enrichment

- Partner onboarding and notifications

- Multiple circularity execution modalities

KEY CAPABILITIES

Accelerate asset circularity with equipment traceability

Implementing asset circularity with Wisechain’s traceability solutions enables manufacturers to accelerate Circularity.

By systematically tracking equipment location, and ownership, manufacturers can accurately plan takeback activities, coordinate partners and increase remanufacturing and recycling.

With these capabilities, manufacturers not only meet evolving regulatory demands but can also unlock new revenue streams in remanufacturing and refurbished markets.

Start transforming your asset lifecycle management today and lead the way in industrial circularity.